In an period outlined by heightened environmental awareness and stringent rules, the manufacturing sector faces unprecedented tension to undertake sustainable methods. shoppers, organizations, and governments alike are significantly prioritizing eco-helpful goods and processes. For industries like cable manufacturing and power cable suppliers, customarily reliant on useful resource-intensive supplies and Power-consuming manufacturing, this shift presents the two a challenge and an important possibility. organizations that proactively embrace environmental accountability are not just contributing into a healthier World; These are strategically creating model value, improving consumer check here loyalty, and securing a aggressive edge. This exploration delves into how leveraging eco-welcoming elements and inexperienced creation strategies transforms a cable company's and ability cable supplier's id and industry situation.

Table of contents:

Eco-pleasant substance range: The Foundation of eco-friendly Cabling

eco-friendly manufacturing procedures: reducing the production Footprint

Sustainable solution design and style: making Longevity and Efficiency

Environmental Certifications & benchmarks: Demonstrating Commitment

Greening the availability Chain: Extending duty

close-of-existence Management: Closing the Loop

upcoming Instructions & Innovation: Pushing the Boundaries of Sustainability

Eco-pleasant content choice: the muse of eco-friendly Cabling

The journey to sustainability begins on the source: the products made use of. Forward-imagining cable companies are going beyond conventional decisions, actively seeking and utilizing greener choices.

Recyclable and Sustainable products: A Most important emphasis is definitely the incorporation of products which might be correctly recovered and reused. This contains making use of Sophisticated PVC formulations that are direct-absolutely free and made for a lot easier recycling, or shifting in direction of thermoplastic elastomers (TPEs) and polyolefins recognized for their recyclability. Some companies are Checking out the use of recycled copper and aluminum, reducing the immense environmental impression associated with virgin metal extraction and processing. Incorporating sustainably sourced or recycled plastics not just conserves normal sources and also often involves much less Vitality to approach as compared to virgin resources.

lower-Carbon Footprint supplies: The embodied carbon of products is actually a essential factor. suppliers are investigating and adopting supplies manufactured using renewable Power sources or procedures that inherently produce much less greenhouse gas emissions. This could possibly entail sourcing polymers from suppliers with documented minimal-carbon production or Discovering bio-based mostly plastics derived from renewable means like corn starch or sugarcane, that may give you a drastically reduced carbon footprint in excess of their lifecycle in comparison with petroleum-dependent counterparts. utilizing these elements aids align goods with green making specifications and satisfies the increasing demand for elements contributing to Over-all Vitality effectiveness and lowered environmental effect.

Non-Toxic product selections: Ensuring products basic safety for equally human overall health as well as the ecosystem is paramount. Adherence to laws such as the Restriction of harmful Substances (RoHS) directive is now a baseline expectation. primary makers go additional, proactively removing perhaps destructive substances even wherever not legally mandated. This includes phasing out halogens (creating Low Smoke Zero Halogen - LSZH cables, essential for safety in enclosed Areas), phthalates, and heavy metals like lead and cadmium. applying non-toxic materials not simply ensures compliance but builds trust with shoppers concerned about well being, security, and long-phrase environmental contamination.

Green manufacturing procedures: Minimizing the producing Footprint

Beyond products, the production system alone provides substantial prospects for environmentally friendly innovation. Optimizing functions to reduce Electricity intake, waste generation, and pollution is essential to developing a truly sustainable model.

Electrical power Efficiency systems: Cable manufacturing is Strength-intensive. employing Electricity-saving measures yields equally environmental and economic Gains. This will involve purchasing superior-effectiveness motors for extrusion strains and drawing machines, upgrading to LED lighting in the course of services, optimizing heating and cooling systems, and most likely recovering squander heat from processes like curing or annealing. Some firms are even buying on-website renewable Strength era, which include solar panels, to additional lower reliance on fossil fuels and decrease operational carbon emissions.

Waste Reduction and Circularity: A lean and environmentally friendly producing technique minimizes waste at every stage. This consists of precise material calculation to reduce scrap, advanced segregation programs for different waste streams (metals, plastics, packaging), and developing closed-loop methods where by attainable. For illustration, polymer scrap could be reground and reused in non-vital apps or sent to specialized recyclers. Water employed for cooling is often addressed and recirculated, minimizing use and discharge. These practices not just cut down landfill load but in addition reduce Uncooked content expenses.

clean up Production Techniques: reducing environmental pollution is crucial for dependable production. This entails applying Sophisticated filtration methods to capture airborne particulates from extrusion or compounding processes, working with closed-loop solvent Restoration programs where relevant, and guaranteeing extensive wastewater therapy to remove contaminants prior to discharge. Adopting cleaner creation technologies assures compliance with environmental permits and demonstrates a commitment to safeguarding area ecosystems and community overall health.

Sustainable solution structure: constructing Longevity and Efficiency

The environmental impact of a cable extends significantly past its production; its functionality and lifespan are equally crucial. Sustainable structure concepts deal with sturdiness, efficiency, and stop-of-existence issues.

toughness and prolonged products Lifespan: building cables for max toughness is inherently sustainable. sturdy construction, higher-top quality insulation and jacketing elements resistant to abrasion, UV radiation, chemicals, and Severe temperatures mean cables last for a longer time. This minimizes the frequency of substitution, conserving means, reducing set up disruption, and drastically chopping down on the volume of Digital squander generated over time. A reputation for dependability and longevity results in being a robust aspect of brand name worth.

large-effectiveness and Strength-Saving options: Cables are conduits for Strength, and inherent losses come about in the course of transmission. makers can improve patterns to minimize these losses. This consists of applying significant-conductivity copper or aluminum conductors appropriately sized for the application and utilizing Sophisticated insulation resources with very low dielectric losses. Cables created for reduce Electrical power loss add straight to the Electricity efficiency from the systems they are part of, minimizing operational fees and the overall carbon footprint for the end-user.

extended Lifecycle Design Philosophy: serious about all the products lifecycle, from cradle to grave (or ideally, cradle to cradle), influences structure alternatives. This might entail planning for a lot easier disassembly at stop-of-lifestyle, applying products which are quickly identifiable and recyclable, or minimizing using composite elements which are challenging to independent. This foresight facilitates more practical recycling and resource Restoration later on.

Environmental Certifications & requirements: Demonstrating Commitment

3rd-occasion validation gives credible proof of the producer's environmental statements. reaching identified certifications and adhering to stringent benchmarks builds rely on and differentiates a brand inside a crowded marketplace.

Obtaining eco-friendly Certifications: Certifications like ISO 14001 (Environmental Management methods) show a scientific method of taking care of environmental impacts. solution-specific eco-labels or certifications (pertinent to certain locations or industries) further more sign compliance with demanding environmental conditions, covering elements from product sourcing to Electricity use and recyclability.

Compliance with business Environmental specifications: Meeting or exceeding marketplace-unique environmental regulations and voluntary criteria is vital. This features compliance with directives like RoHS and arrive at (Registration, analysis, Authorisation and Restriction of Chemicals) in Europe, in addition to aligning with prerequisites for eco-friendly developing certifications (e.g., LEED, BREEAM) which often mandate lower-emitting components or distinct environmental product declarations (EPDs).

Eco-style ideas and Environmental Labeling: Proactively incorporating eco-design ideas through the entire products advancement system enables brands to enhance environmental overall performance from the outset. clear environmental labeling, which include EPDs, supplies shoppers with specific, verified information regarding an item's environmental footprint, enabling educated purchasing choices and boosting brand transparency.

Greening the availability Chain: Extending obligation

A company's environmental footprint extends further than its personal functions to its overall source chain. Collaborating with suppliers and logistics companions on sustainability initiatives is essential.

Supplier Environmental specifications: Responsible producers ever more vet their suppliers dependant on environmental functionality. This will contain audits, questionnaires, demanding suppliers to carry certifications like ISO 14001, or demanding traceability for Uncooked resources to ensure These are sourced responsibly and ethically. Collaborating with suppliers on environmentally friendly initiatives can generate advancements all through the value chain.

inexperienced Logistics and Transportation: The environmental affect of transporting Uncooked components and completed goods may be sizeable. procedures to reduce this include things like optimizing delivery routes, consolidating shipments, using gas-economical cars or alternative transport modes (like rail or sea freight where by possible), deciding upon packaging made out of recycled or recyclable resources, and reducing General packaging quantity.

finish-of-Life Management: Closing the Loop

legitimate sustainability requires getting duty for solutions even right after their helpful existence finishes. Implementing productive Restoration and recycling programs is the final bit of the puzzle.

Cable Recovery and acquire-again Programs: Leading manufacturers might partner with distributors or specialized recycling companies to aid the gathering and recycling of aged cables. providing take-again plans encourages prospects to dispose of utilized cables responsibly, blocking them from ending up in landfills and enabling the Restoration of useful elements like copper and aluminum.

Sustainable products Lifecycle Management: This holistic method will involve managing the environmental impacts of an item through its complete lifecycle. It emphasizes developing for recyclability, collaborating with recyclers to enhance recovery processes, and contributing to your round financial state where by supplies are kept in use for as long as probable, extracting optimum value and after that recovering and regenerating merchandise and products at the end of their service existence.

long term Directions & Innovation: Pushing the Boundaries of Sustainability

The pursuit of sustainability is really an ongoing approach, driven by continual innovation and technological advancement.

analysis & growth in environmentally friendly elements: sizeable R&D effort and hard work is becoming directed to building upcoming-generation cable products that happen to be a lot more sustainable. This contains Discovering Sophisticated bio-polymers with enhanced efficiency qualities, researching biodegradable products for precise applications, and locating techniques to incorporate bigger percentages of recycled content material with out compromising good quality or safety.

Green engineering Innovation: Manufacturers are leveraging technological improvements to even more minimize their environmental influence. This consists of implementing good producing (business four.0) ideas for actual-time Electricity checking and optimization, utilizing State-of-the-art information analytics to minimize waste, and exploring novel, much less Electrical power-intensive processing techniques.

Embracing eco-helpful components and environmentally friendly production procedures is not a niche action but a strategic critical for the modern cable marketplace. It transcends mere compliance, starting to be a cornerstone of name identity and value. By prioritizing recyclable and non-poisonous components, optimizing output for Vitality efficiency and waste reduction, building strong and economical merchandise, acquiring credible certifications, greening the provision chain, and preparing for conclusion-of-daily life management, producers Make resilience, improve their track record, and bring in environmentally acutely aware shoppers and companions. providers main this demand, normally a devoted electricity cable supplier or ability cable producer, realize this synergy deeply. For instance, initiatives viewed inside of businesses like JINDA CABLE replicate a rising marketplace determination to integrating these inexperienced ideas, demonstrating that environmental duty and company achievements can, and without a doubt have to, go hand in hand to power a sustainable long run.

Nancy Kerrigan Then & Now!

Nancy Kerrigan Then & Now! Susan Dey Then & Now!

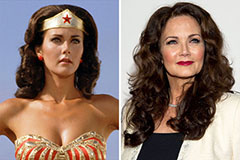

Susan Dey Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Bo Derek Then & Now!

Bo Derek Then & Now! Justine Bateman Then & Now!

Justine Bateman Then & Now!